Innovation and Precision on the Rails

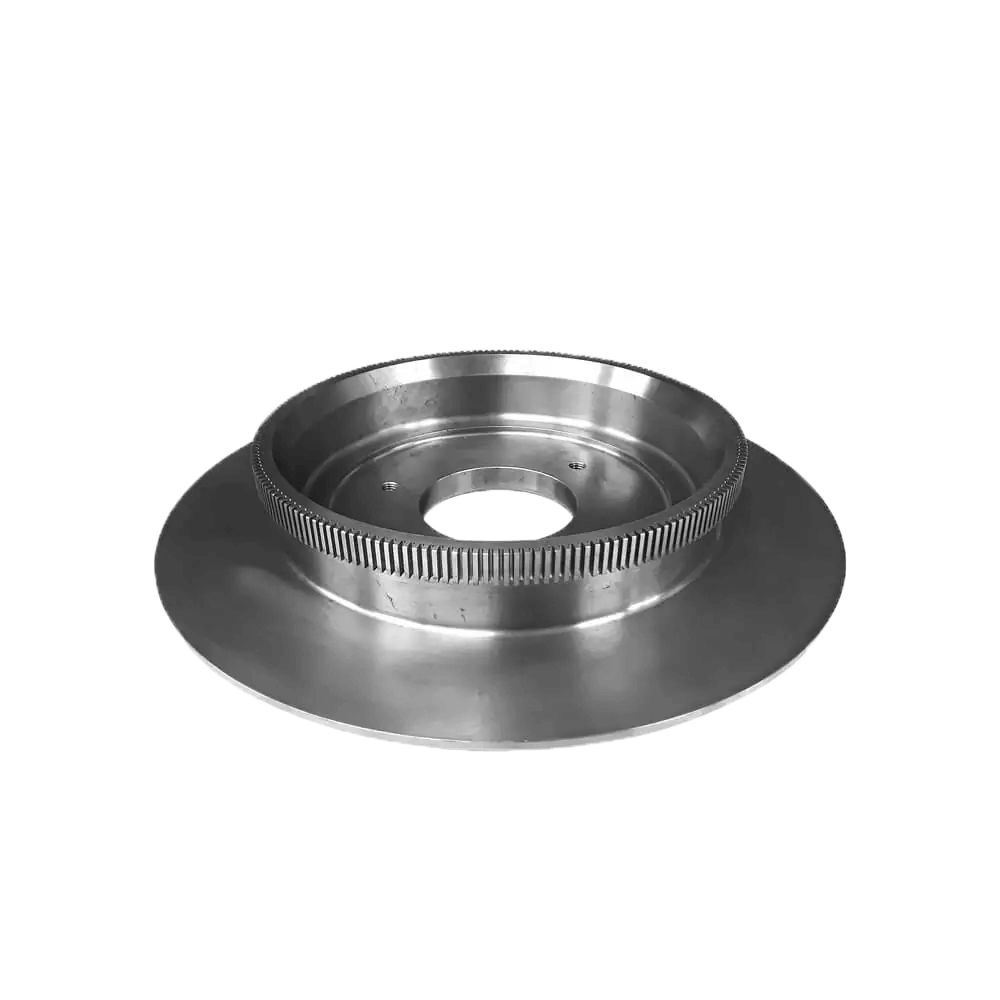

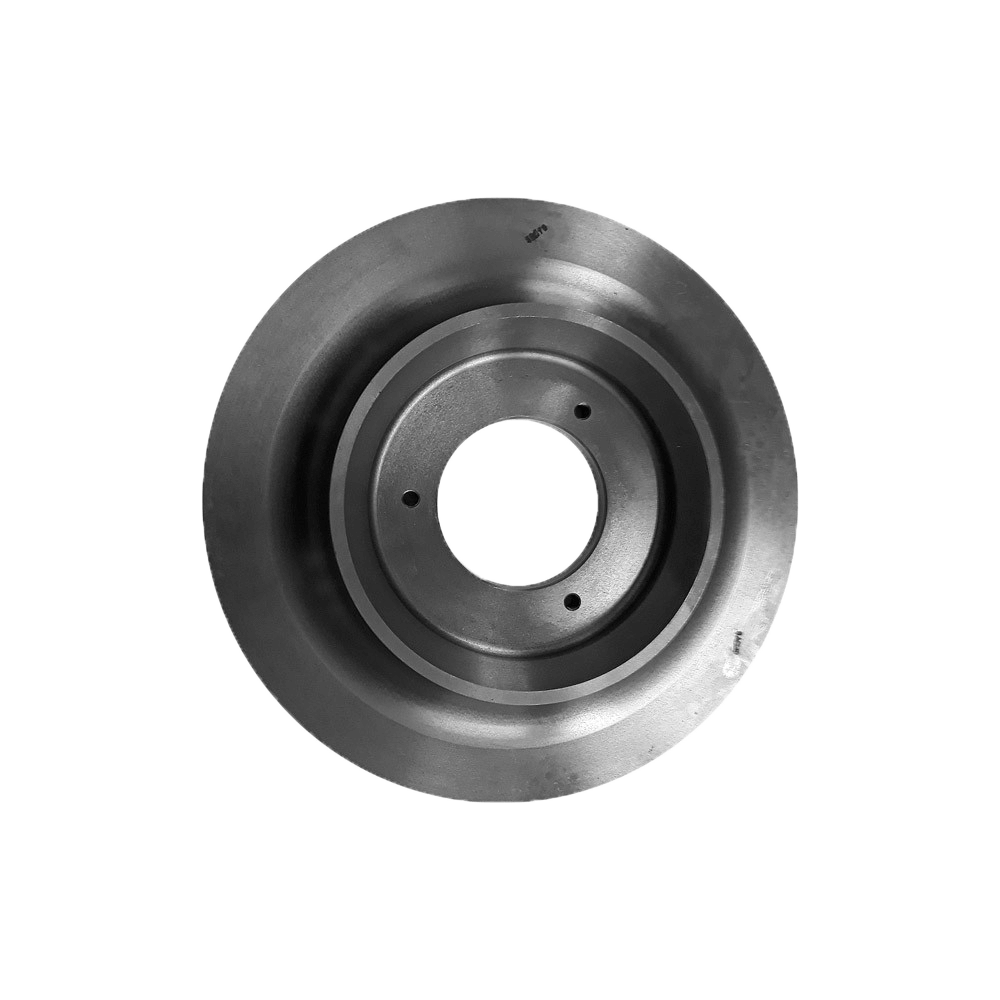

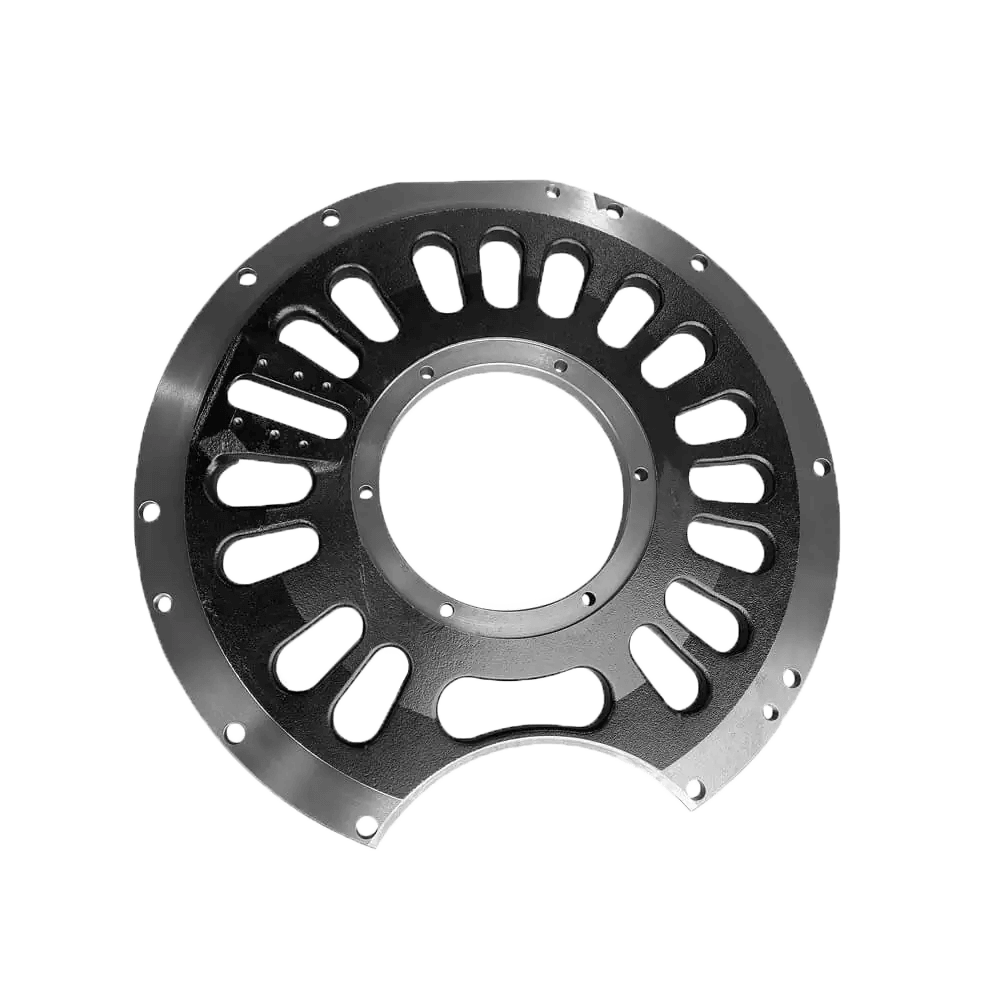

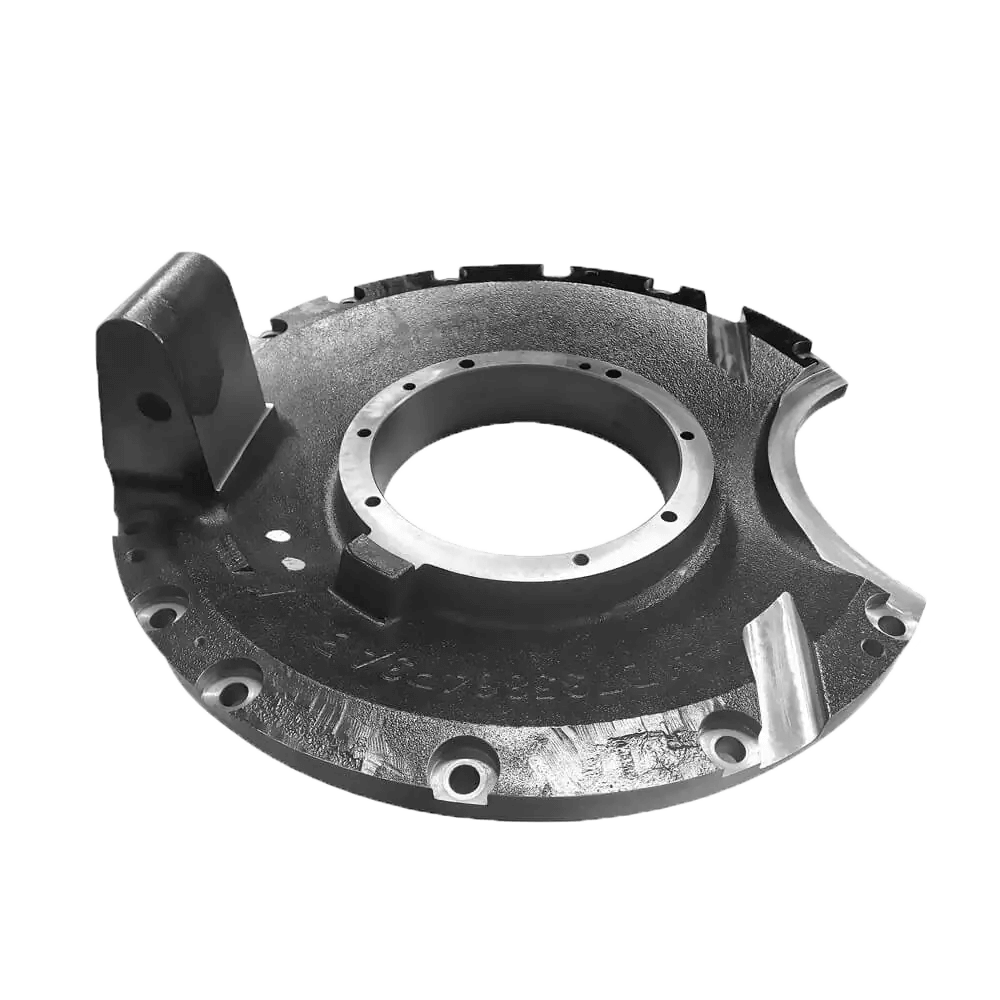

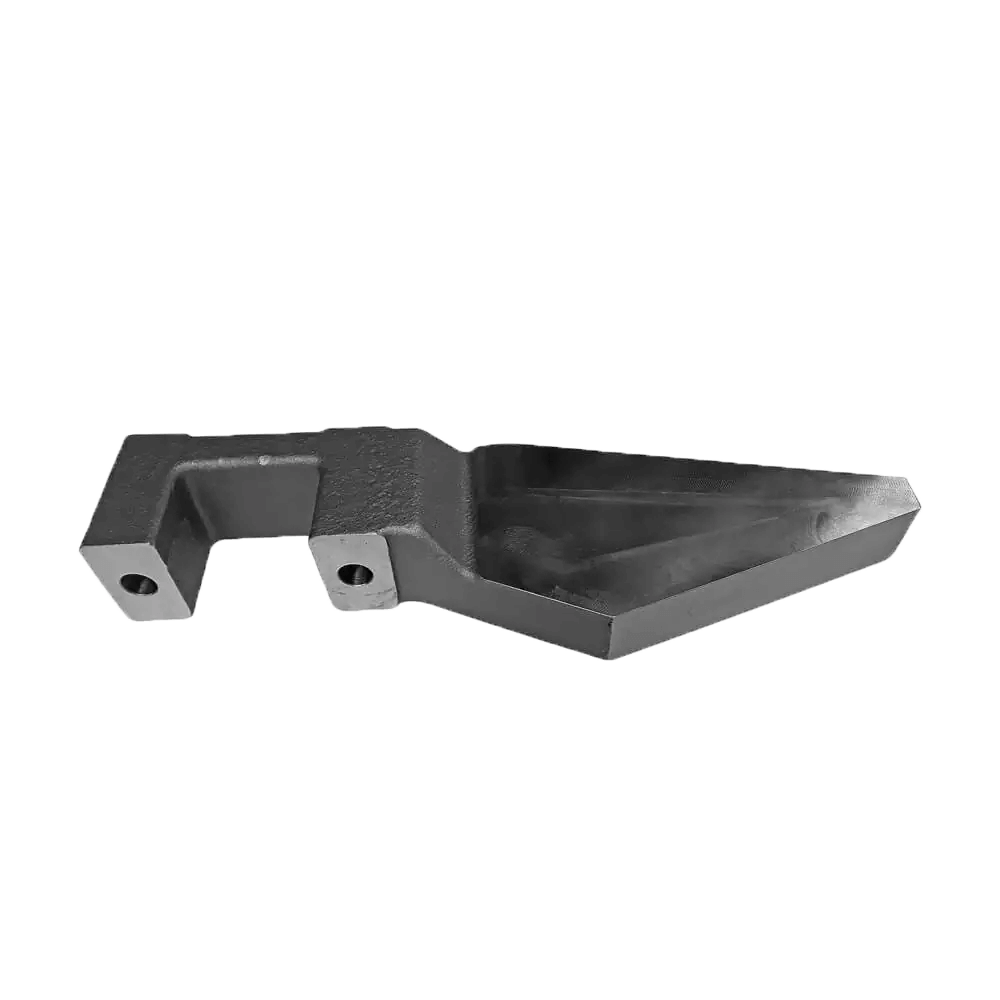

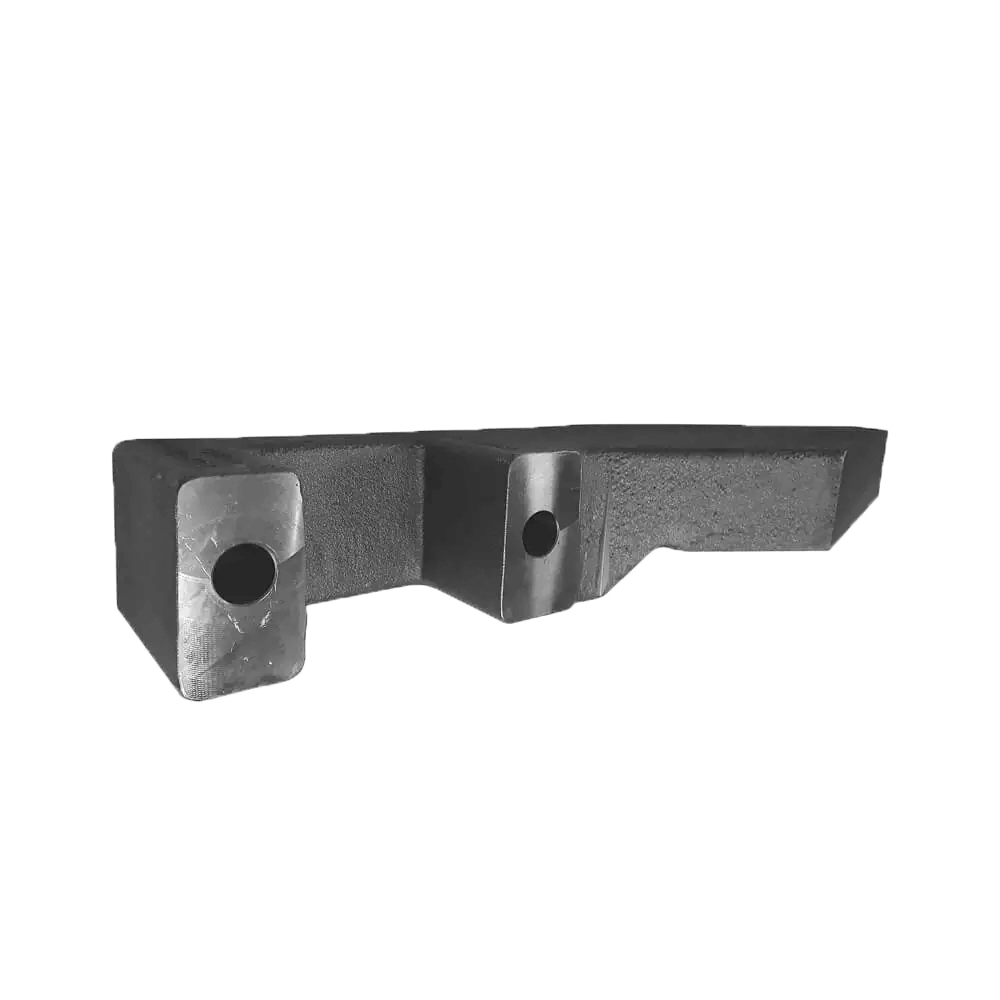

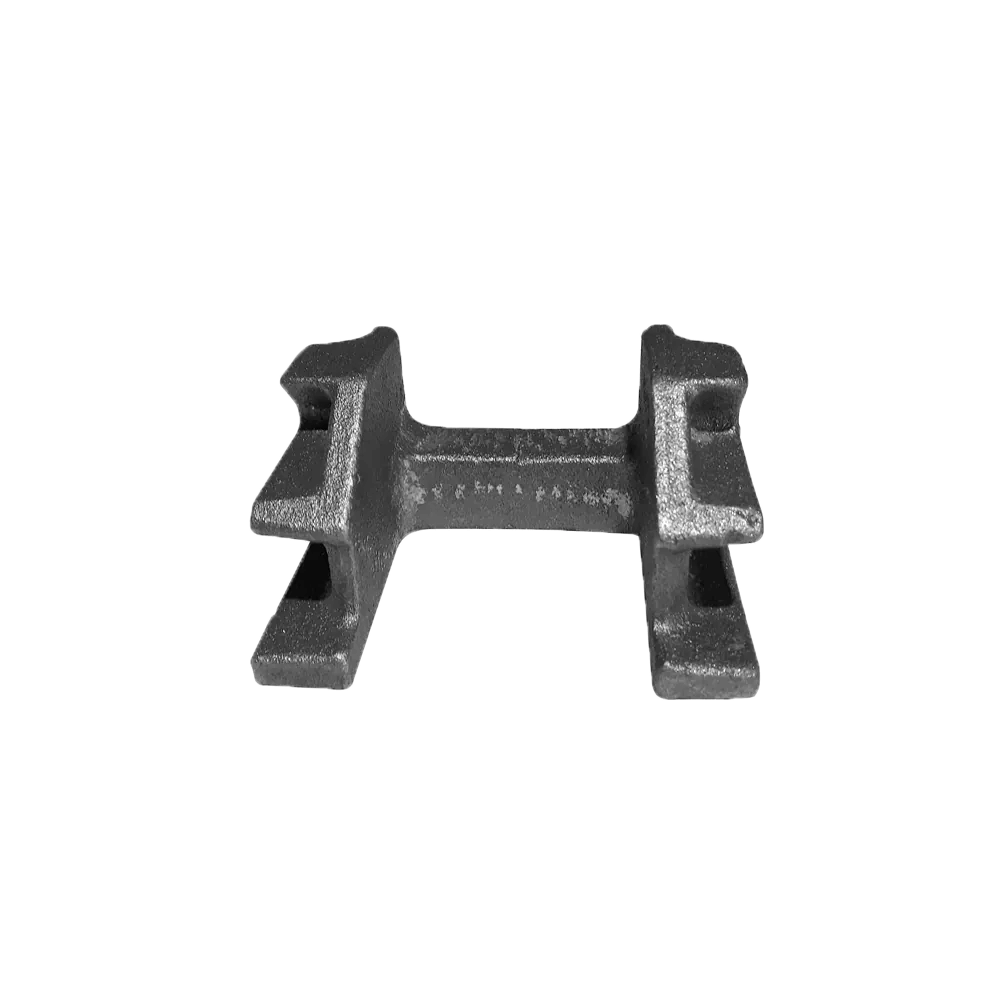

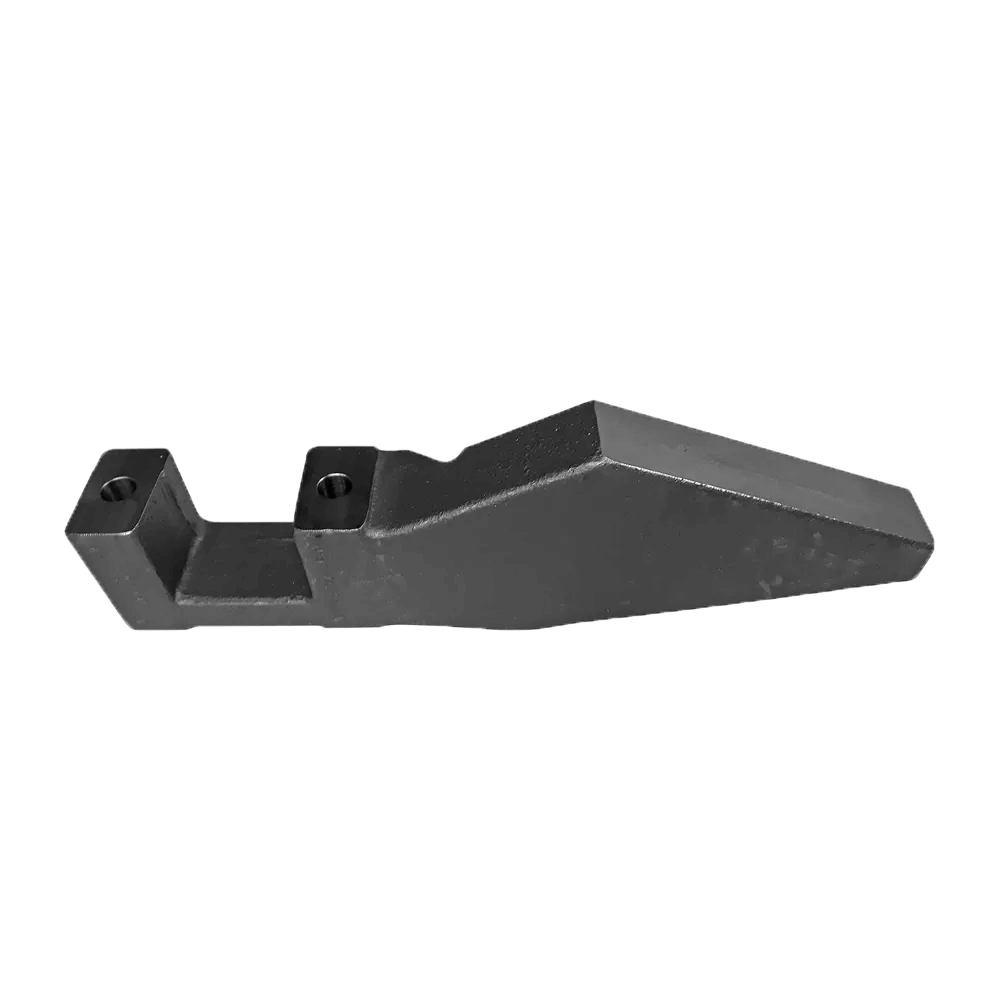

Since 2011, RIO has been contributing to the railway sector, initially supplying shoulder blocks for steel sleepers. With a commitment to innovation and quality, we expanded our portfolio to serve permanent tracks and manufacture locomotive traction engine parts. We also develop specialized tools for railway maintenance, ensuring efficient solutions for the sector.

Our products are developed under strict quality standards, complying with various international norms and certifications. We work with a wide range of metal alloys to meet railway market demands, ensuring durability and high performance. We are certified under ISO 9001, ISO 14001, and IATF 16949, guaranteeing efficient production processes, responsible environmental management, and superior quality.

To optimize new product development, we invest in 3D printers in our prototype factory. From a 2D part design, we can reduce costs and speed up the production process, delivering innovative solutions.

Our foundry stands out for its wide variety of molding processes and expertise in more than 80 alloys and material classes. With great production flexibility and advanced technical knowledge, we guarantee innovative and high-performance solutions for your projects.

Our machining operations rely on a diverse technological park equipped with horizontal and vertical machining centers, CNC machines, and high-precision grinders. This infrastructure allows us to offer maximum flexibility and quality, ensuring excellence in product finishing and performance.

Arthur Araujo dos Santos

dpo@rio.expert

Namecheap | 26-2368289

© 2024 Rights Reserved – Metalúrgica Riosulense S.A. Privacy Policy