Aware of our role in society, we develop projects in the areas of education, culture, health promotion, environmental preservation and respect for diversity. Our goal is to bring quality of life to our team, our partners, and the local community.

RIO developed the Commemorative Planting project, in which native tree seedlings are planted by employees every 5 years they complete the company. The action has taken place annually since 2002, preferably in the month of September, in reference to Arbor Day, and is carried out on the company’s own land, which has a vast green area.

The project consists of a production line within the facilities of the São Cristóvão do Sul penitentiary, where it uses exclusive labor from inmates. It encourages diversity, equity and inclusion, by enabling reintegration into society through: professional training, reduction of sentences, generation of income for their families and even hiring after serving a sentence.

The focus of the program is to promote and recognize improvements in production and administrative processes made by our employees here at RIO, encouraging creativity and innovation.

Carried out in partnership with Senai, the program aims to train young people aged 16 and 17 to work in the industry. Thus, in addition to the theory obtained in the classroom, students have their first contact with the administrative, engineering and production areas, putting their learning into practice here at RIO.

We were one of three investing companies in the Selo Social program, in Rio do Sul, helping to make socio-environmental projects possible for several organizations in the city. This is a program run by the NGO Instituto Abaçaí that helps municipalities develop in areas such as education, health, environment, culture, inclusion, economy, politics and urbanization.

The flame adopted the smile! We implemented reverse recycling logistics proportional to 30% of the orange boxes we distributed on the market. This is so that the recycling rate is increasingly higher in the country.

We work with the segregation of waste and its classes into specific and identified containers (colors). Employees collect waste and deposit it at our center. Afterwards, the correct final destination is given according to the class of each waste; Today we send an average of 74.5% of all waste generated in the company for recycling.

RIO is committed to acting in a socially responsible manner. It is our policy to refrain from acquiring Conflict Minerals from the Democratic Republic of the Congo that could finance or benefit armed groups in the DRC or an adjacent country – directly or indirectly, from any source. It is a requirement that our partners do not supply RIO with any products that the supplier cannot certify as “Conflict Free”.

The energy consumed in the industrial park and throughout the RIO area is 100% from renewable sources.

100% of ADF is sent to partners for use in cement artifacts and road paving.

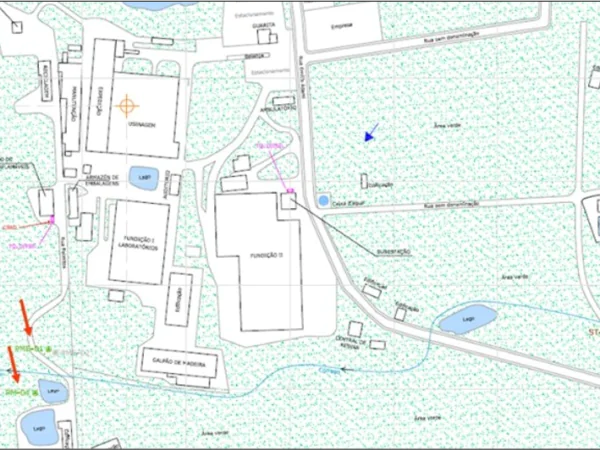

Groundwater control is carried out annually through four monitoring wells installed in the industrial park.

The process of water collection at the WTP begins with the flow of the surplus of four bodies of water located in the upper areas of the terrain, four lakes that flow into a stream. The waters that come out of these bodies of water flow through a natural gravity process and are stored in the body of water located to the left of the ETA. The ETA treats both drinking water and the water used in the furnaces. Both collected from nearby lagoons.

The Effluent Treatment Station (ETE) is composed of a wastewater treatment system for industrial and/or sanitary water, carried out by means of physical-chemical and biological processes. All the recoverable effluent generated in manufacturing processes, as well as the effluents from sinks, bathrooms and kitchens, are received at the ETE. After treatment, the treated effluent is reused in the cooling towers of the induction furnaces.

Arthur Araujo dos Santos

dpo@rio.expert

Namecheap | 26-2368289

© 2024 Rights Reserved – Metalúrgica Riosulense S.A. Privacy Policy