Integrated processes to create your projects with high quality and technology

With expertise in materials, foundry, and machining, we have been manufacturing high-precision parts since 1946. We serve the Brazilian market and export to more than 25 countries, standing out for quality, technology, and innovation across various industries.

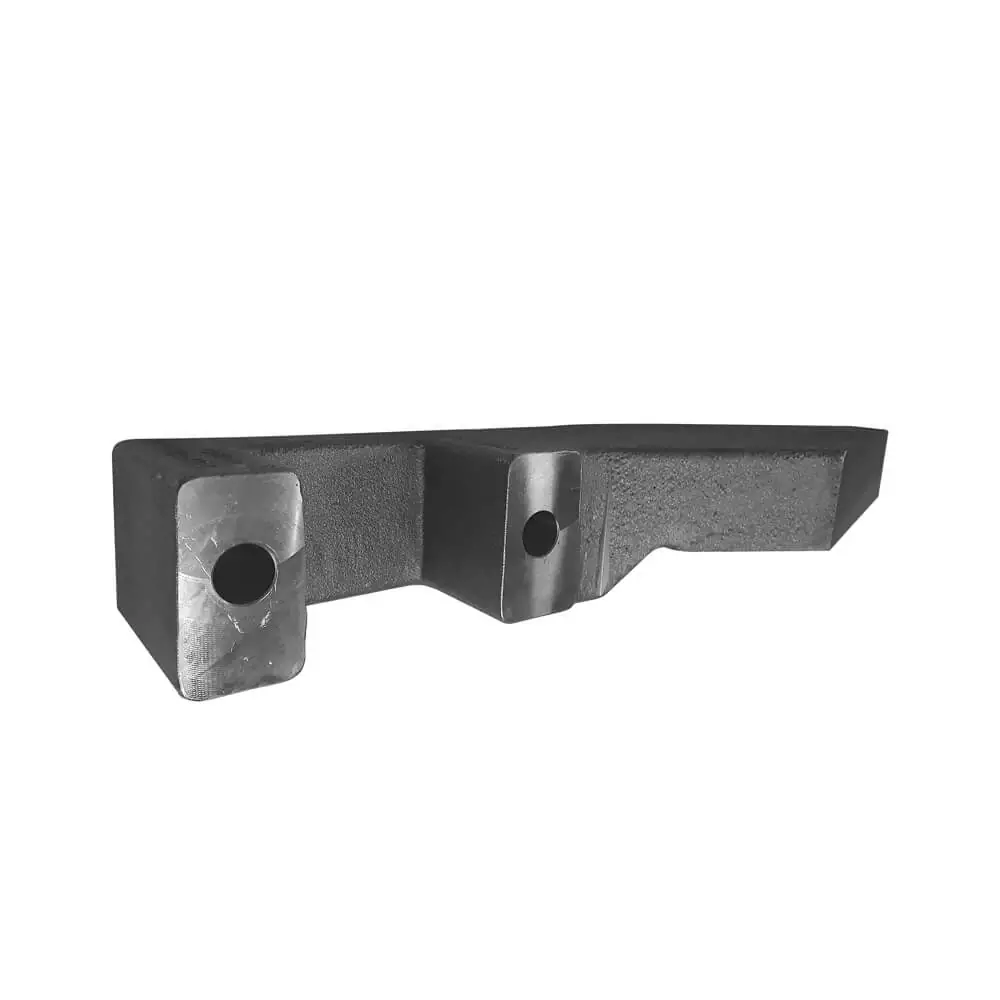

The tradition and trust in our brand was built in the foundry field. With modern and intelligent processes, we produce parts from 0.010 kg to 150 kg—or according to project analysis—in more than 80 ferrous alloys and classes of materials.

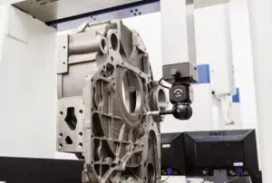

We have a wide variety of processes through horizontal and vertical machining centers, ensuring high precision and quality in our parts.

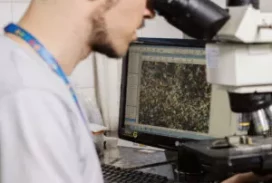

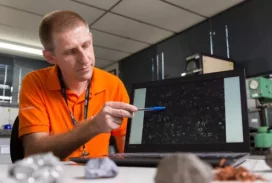

Our fully equipped metrology and material analysis laboratories ensure autonomy and agility in every stage.

For over 20 years, our employees have planted native trees in the industrial park for every 5 years of service at RIO.

With a production line inside the São Cristóvão do Sul penitentiary, the project employs inmate labor, fostering diversity, equity, and inclusion.

Focused on promoting and recognizing improvements in production and administrative processes made by our employees, encouraging creativity and innovation.

Carried out in partnership with Senai, the program aims to train young people aged 16 and 17 to work in the industry.

We implemented reverse logistics recycling equivalent to 30% of the boxes we distribute to the market.

Using specific containers separated by colors, about 74% of all waste generated by the company is sent for recycling.

100% of the energy consumed in the industrial park and throughout RIO facilities comes from renewable sources.

100% of ADF is sent to partners for use in cement products and road paving.

Groundwater control is carried out annually through four monitoring wells installed in the industrial park.

With a strong presence in the OEM market, RIO serves the main truck and bus manufacturers and system suppliers, supporting customers in all stages of project development. In addition to the domestic market, we also operate internationally, with presence in the Americas, Asia, and Europe.

Partnering with major manufacturers in the sector, RIO has been active since 2011, both nationally and internationally. Our extensive product range includes supports, housings, tubes, structural parts, and engine components.

We began supplying this market in 2011 with shoulder blocks and steel sleepers. Over time, we expanded our portfolio to include permanent track parts and locomotive traction engine components. We also develop tools used in railway maintenance.

We have been supplying engine parts to this market for over 10 years. Currently, we are expanding our portfolio to include larger structural parts, following the demand of the Brazilian market driven by multinational investments in local factories.

We entered this market by producing marine manifolds and developing other parts based on customer projects and needs.

We began serving the OEM corporate market – Original Equipment Manufacturer – in 1994 with parts for Mercedes-Benz. Since then, the portfolio has expanded a lot and today brands such as AGCO, Agrale, Cummins, MAN, MWM, Scania, Stara, Suspensys, Volvo, Vale, Valtra, Hidremec, among

others rely on our capacity and quality in product development.

For the railway market, we began supplying steel sleeper shoulders in 2011. Previously, we increased our portfolio by developing parts to service permanent lines, as well as manufacturing parts for locomotive traction engines. We also develop tools used in railway line maintenance, to further meet the needs of this market.

Our products are developed in compliance with the various international quality standards and certifications in the various metal alloys that these markets require.

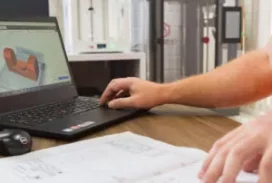

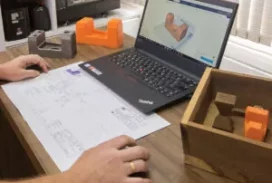

And to offer agility as well as cost reduction in the development of new products, we use the manufacture of models with 3D printers in our prototype factory, using a 2D drawing of the part.

Our processes are integrated, providing fast and precise responses to your needs:

With humanized service, all our efforts and expertise are directed to delivering the best and most complete solutions for your projects.

Our comprehensive laboratory structure for materials and dimensional testing evaluates quality and meets the strictest requirements. We hold certifications such as VDA and IATF 16949 to validate all projects.

Our tradition and reliability were built in the foundry field. With modern and intelligent processes, we produce parts from 0.010 kg to 150 kg (molding box 1,100x800x400 mm).

Our equipment allows us to combine speed with high precision in a variety of machining operations. We handle different part dimensions, such as oversized items and tolerances up to 1mm in Valve Guides and 2mm in Valve Seats.

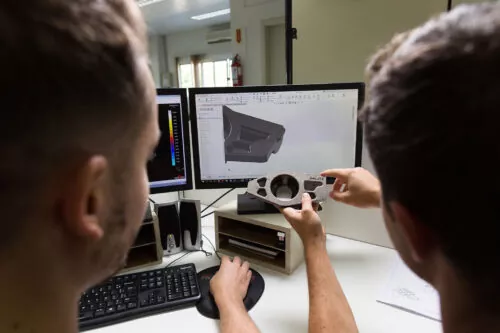

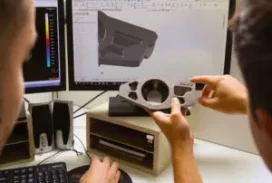

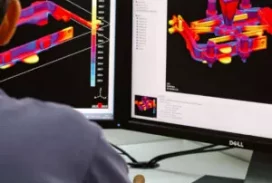

We design and develop parts with all types of geometry. Our full metrology and physical-chemical analysis laboratories ensure autonomy and agility in every stage. We apply MAGMA technology to optimize foundry processes and EDGECAM technology for machining.

We specialize in the development of metal alloys, always offering the best option and treatment for each application. Our portfolio includes over 80 alloys and classes of materials.

With our prototype factory, you reduce time and cost in project development. We combine 3D technology with engineering simulation tools and advanced equipment to deliver the best results.

As one of the largest manufacturers of engine components, automotive and structural parts, we produce small, medium, and large parts in cast iron (ductile, gray, white, and superalloys) and steel (with a wide variety of alloys).

With more than 75 years of expertise, we are specialists in the development of metallic alloys, always providing the best option and treatment for each application. Our portfolio includes over 80 alloys and classes of materials.

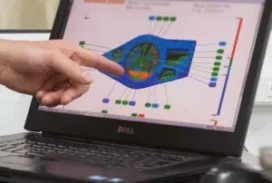

Through 3D printing, we enable corrections before casting, ensuring agility in the production of complex parts and high dimensional stability. With RIO’s know-how in this technology, we deliver accuracy and optimized development times for customer projects.

In addition to creating and developing parts with all types of geometry, our complete metrology and materials analysis laboratories ensure quality in every step. We apply MAGMA technology to optimize casting and EDGECAM for machining.

Prototype Factory

We have developed a process in which we use additive manufacturing, through 3D printing, to manufacture casting models, ensuring high quality and dimensional stability. Thus, you can reduce the Time to Market of your prototypes by more than 50%.

3D technology and processes: Prototypes are produced using our experience in the development of metal alloys and our technical casting know-how. We combine 3D technology with engineering simulation tools and cutting-edge machining equipment, offering agility and guaranteeing the shortest deadlines in the development of cast prototypes.

The quality of the prototypes is assured, as they are produced on the same lines and subjected to the same processes as current products for the OEM market.

Arthur Araujo dos Santos

dpo@rio.expert

Namecheap | 26-2368289

© 2024 Rights Reserved – Metalúrgica Riosulense S.A. Privacy Policy