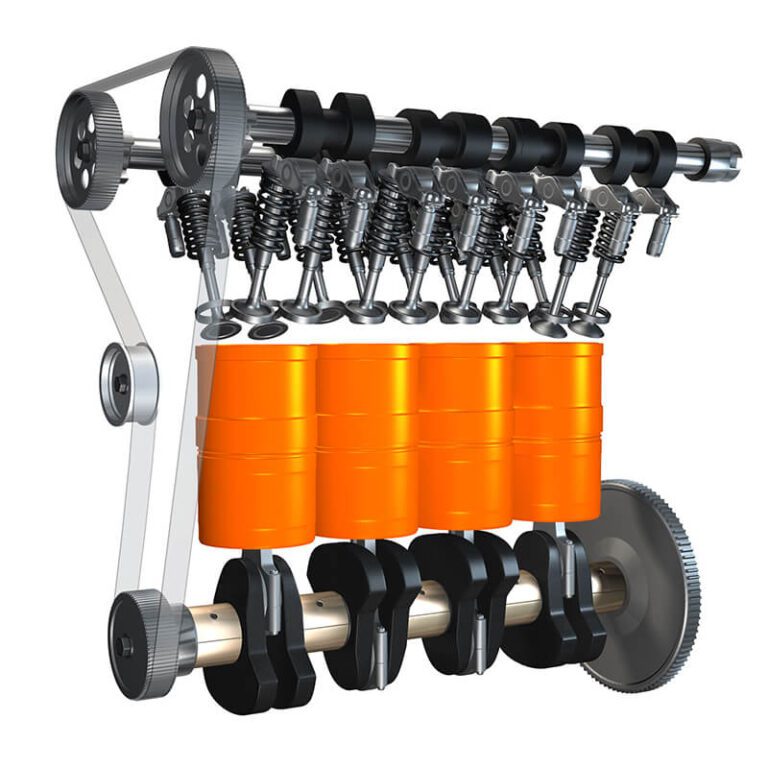

The main function of the cylinder liners is to seal the combustion chamber, allowing the thermal exchange of heat throughout the block. Its use allows the reuse of the block, maintaining its useful life.

Benefits of RIO cylinder liners

- Internal finishing of the wet liners according to manufacturer’s standards (pre-softening).

- Over metal of dry liners in 0.80 mm in the internal diameter.

- Dimensional standardization of the parts that make up the package: guarantee of reduced rework.

- Rough Bushings for adaptation/ recovery of liners in blocks.

- Oversize up to 4mm.

- Standard hardness.

- Alternatives for high performance engines.

- One of the largest mixes of the market

- Special alloys with resistance to wear and corrosion.

- Innovative packaging for the wet liners: guarantee of integrity until delivery to the final customer.