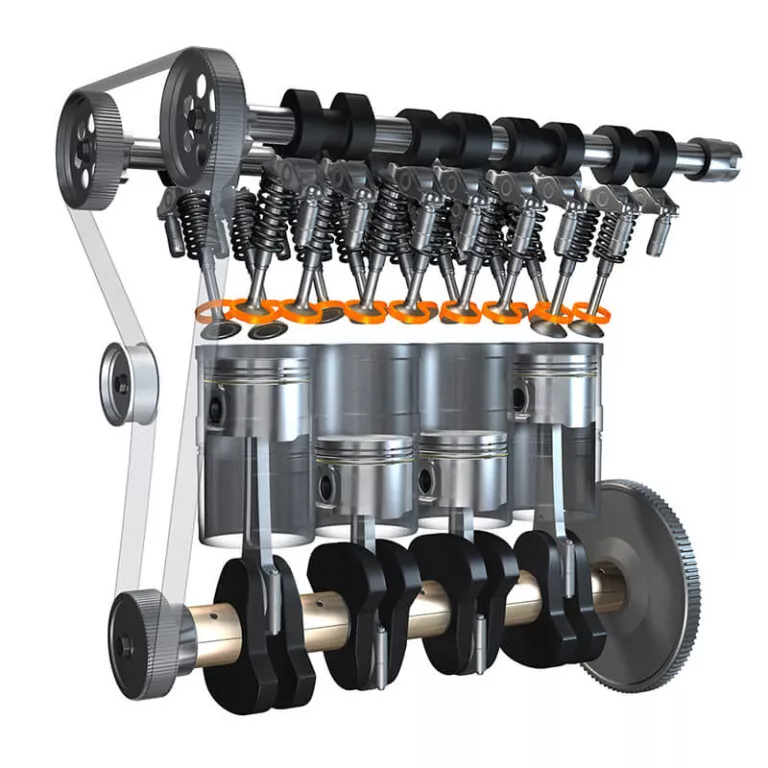

The valve seats are nothing more than rings on the cylinder head that serve as a “bed” for the base of the valves (exhaust or intake), sealing the compression or explosion inside the combustion chamber.

Largest portfolio in the market

Oversizes up to 2 millimeters: greater use of the life span of cylinder heads

Four types of materials for applications according to the engine requirement: cast iron, tempered cast iron, tempered steel and super alloyed steel.

As these products are subjected to high temperature wear stresses, high chromium and nickel steels, cast irons alloyed with molybdenum and chromium or nickel and cobalt based alloys are applied according to the engine’s requirements.

Special pieces in both material and dimension.

Contraction study – valve seats of cylinder head

We put into practice a series of tests simulating common conditions in the recovery of a cylinder head.

See the test criteria:

After the removal of the valves, the condition of the valve seat contact width region must be checked, and in case of wear, they must be replaced.

Also, it is important to observe whether the machining (angle and width) of the seat contact width profile is in accordance with the specifications. The geometry of the profile is extremely important to obtain the proper sealing under the original conditions.

Deregulated valves and camshafts with poor geometry also compromise the service life of the seats and the valves. It is essential, then, to measure the spring load in a dynamometer before installing the valves, as both below and above specification loads cause seRIOus problems for both the valves and the seats.

Arthur Araujo dos Santos

dpo@rio.expert

Namecheap | 26-2368289

© 2024 Rights Reserved – Metalúrgica Riosulense S.A. Privacy Policy